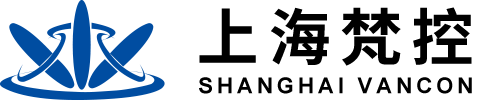

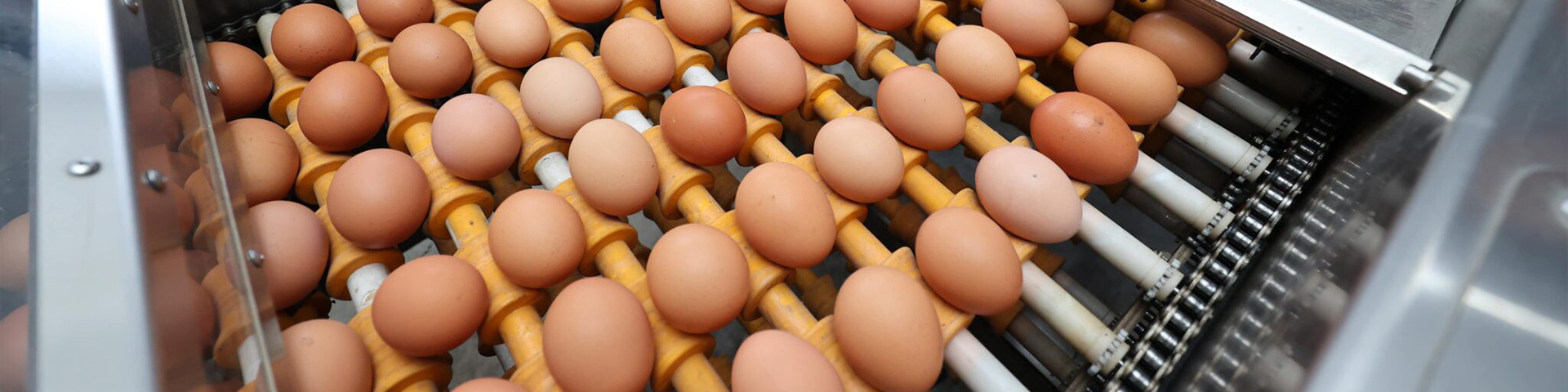

On the tank, eggs are connected to an egg washing machine or accumulator, where users directly put eggs from egg trays or egg baskets into the sink.

Accumulator Connect to the egg washer, arrange the eggs in order, and enter the egg washer. The filling rate of eggs reaches 98%.

In egg production and processing, the egg washing machine is a crucial piece of equipment. It effectively removes dirt, impurities, and microorganisms from the surface of eggs, significantly improving egg quality and safety, and laying a solid foundation for subsequent processing, storage, and sales.

In the egg processing industry chain, the storage and transportation of egg liquid are crucial, and the egg liquid tank is the key equipment in this link. With its excellent design and performance, it ensures the quality stability and safety of egg liquid during processing.

The egg Blending System, according to customer requirements, uses a special emulsifying pump to add sugar or salt to the egg liquid to obtain a special blended egg liquid.

The pasteurizer machine can process various egg products such as regular egg liquid, sugar and salt added egg liquid, heat stable egg liquid, and egg tart liquid.

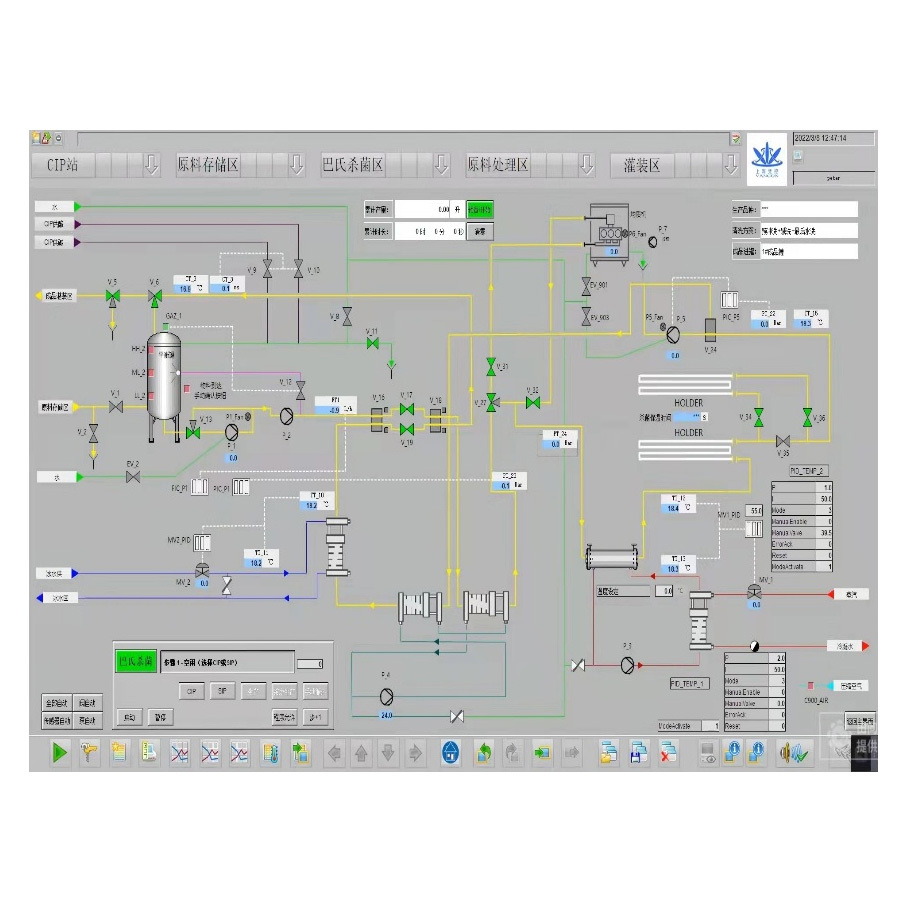

CIP (cleaning in place) refers to a fully or semi-automatic cleaning system that uses pumps and pipes to deliver water and cleaning fluids according to a certain procedure. It achieves cleaning without moving or disassembling the production equipment.

The SCADA system uses automatic valves and sensors to automatically control the entire factory's production process.